Curious about effective controls in the workplace? Want to do everything you can to protect workers from hazards? Of course you do. The hierarchy of controls that OSHA and many other safety organizations promote exists for a reason. It helps mitigate health risks, incidents, and injuries.

Identifying occupational hazards before work is so crucial. We’ll discuss some hierarchy of controls examples and identify the steps to implement these controls.

What Is the Hierarchy of Hazard Control?

The hierarchy of control for hazards is a systematic approach. It begins with the most effective controls and moves down to those considered the least effective.

The ideal is to eliminate every hazard, but that is not realistic. It is realistic to steadily move up the hierarchy risk control pyramid. The more you move up, the closer you get to max safety on the job.

It is common to combine controls. Just remember: the greater the risk, the more effective the control method should be.

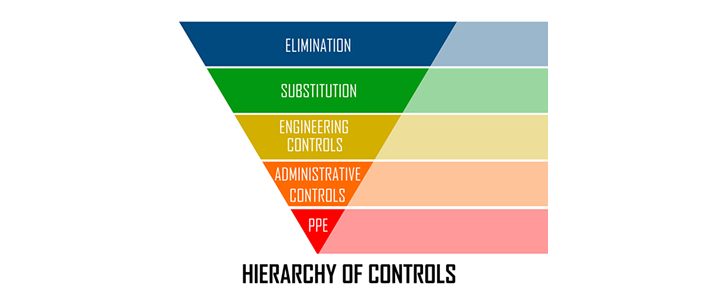

Hierarchy Risk Control Pyramid

Imagine an upside-down pyramid. “Elimination” is at the top. It’s the most sought-after action. Then you have “PPE,” and it falls at the very bottom. PPE is the least effective method in the safety hierarchy of controls.

Move up the pyramid to improve your controls. The implementation isn’t always simple, but it’s certainly worth your time and energy.

Look at the pyramid, beginning with the most effective control.

Elimination

These controls are designed to eliminate hazards. They may also call for completely stopping a practice to get rid of hazards altogether. Essentially, you attack the source. This is the most effective you can be when it comes to preventing potential incidents, injuries, and even fatalities.

Substitution

These controls substitute less hazardous materials or equipment. You might change out chemicals or use machinery that produces less noise.

Engineering Controls

This occurs when workers are isolated from the hazard. You might implement ventilation, blast shields, machine guarding, guard rails, etc.

Administrative Controls

Here, you will find warnings like signs, labeling, and alarms. Administration might also require certain procedures to follow or specific training. Managers may limit exposure or put a buddy system in place. Basically, you change the way people work.

PPE

Sometimes, employers require workers to wear personal protective equipment. Employees wear safety glasses, respirators, gloves, etc. The PPE hierarchy of controls is the least effective, though. You opt to protect the person if or when the incident occurs. In this method, you don’t attack the source – the root of the potential incident. An accident or disaster could still occur.

Hierarchy of Hazard Control Process

There are six main steps in the hierarchy of control of occupational hazards process. They are outlined below so you can get started. For a thorough assessment and a design unique to your company, you’ll likely want to reach out to the professionals.

Safety companies in Houston like Safety by Design understand the hierarchy of hazard controls OSHA stands by. We can help you today! Just reach out.

1. Identify Control Options

Go to your workers. Collect information. Then organize and review it. Notice hazards and look at potential harmful exposure. You will need to review OSHA regulations, industry standards, safety and health publications, manufacturer’s literature, and reports.

Finally, investigate controls that are already in place, and look to the hierarchy for improvement in these areas. Contact a hazard and risk assessment consultant if you don’t know where to start.

2. Select Controls

It is your job as an employer to select controls that are effective. It is also great if these controls can be permanent.

Attempt to attack the root of the hazard. If possible, avoid PPE as your first line of defense. If hazards could lead to illness or death, we strongly recommend that you work to eliminate them as soon as possible.

Note: Avoid controls that will introduce new hazards. For example, if you suddenly require hearing protection, your alarms might not be heard.

3. Develop and Update Your Plan

Your plan will explain how all the controls work and are to be implemented. Begin with your most serious hazards. Update your plan annually (at a minimum). You will also want to update in the event of equipment, process, or environment changes.

Track your progress and be sure to establish ways to measure your hazard controls. It is important to know if they have been implemented and are working.

4. Consider Non-Routine Operations and Emergencies

Think about fires, explosions, chemical releases, spills, shutdowns, natural disasters, violence, attacks, and even disease outbreaks. Procedures should be in place for these uncommon but possible circumstances. This may require modifications of regular operations and controls. Emergency drills are a great way to get everyone familiar with adjusted procedures.

OSHA regulations should be consulted, as well as those of your local emergency responses, state agencies, etc. These procedures need to comply across the board.

If you are unfamiliar with how to make an emergency action plan, reach out to professional safety management consultants for help.

5. Implement Controls

Once you have identified hazards and planned your controls, they should be put into action. If controls are simple and inexpensive, get those in place immediately.

If your resources are limited, attack your worst hazard first. Then as you can, implement new controls elsewhere. Stick to the plan.

6. Follow Up

Inspect and evaluate your controls. Be sure they’re effective. Otherwise, all your work won’t matter. Maintain the controls and be willing to adjust when something isn’t working. Track progress. Ask questions. Confirm that controls and procedures are being implemented properly and followed consistently. Implement safety incentive programs if necessary.

Contact Safety by Design for Professional Risk Assessment

The team at Safety By Design is experienced with compliance and safety training in Houston. Safety is our profession and passion. Let us help you. There is no better time to begin keeping your workplace the safest it can be.

Contact Safety by Design today. Our team will help make your work (and life) easier and safer!